Welcome to “Tuesdays with Scott” segment of the Climate Change program.

Last week, I discussed single junction cells that are part of the first generation solar cells made from crystalline silicon.

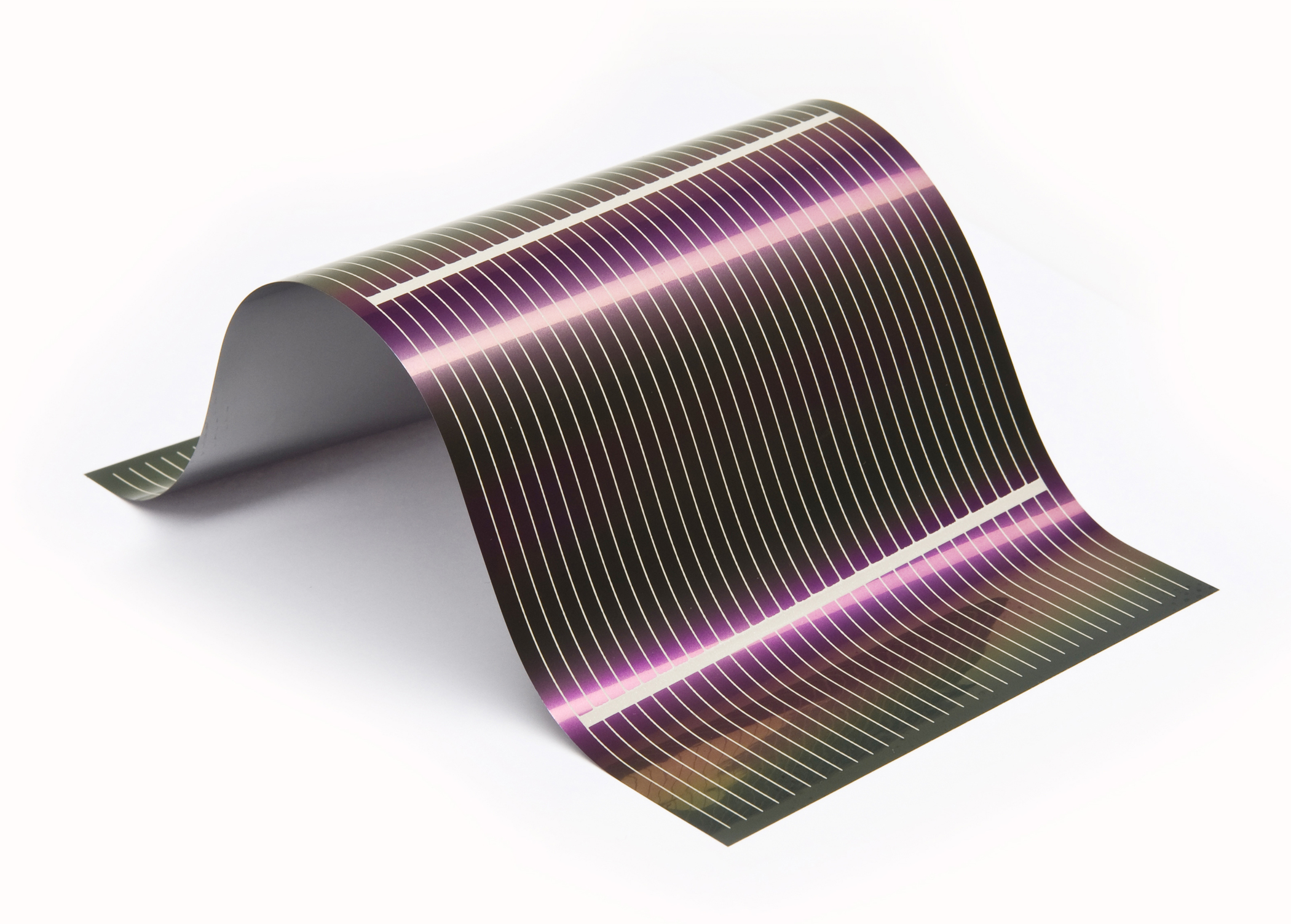

Today, I discuss second generation thin film solar cells. These are not classified as crystalline silicon. These include CdTe, CIGS and amorphous silicon (a-Si).

Starting with amorphous silicon, these are non-crystalline form of silicon used for solar cells and thin film transistors in LCDs, such as a solar calculator. Amorphous silicon solar cells are thin, flexible films that can be applied to glass, metal or plastic. Though one of the most environmentally friendly photovoltaic technologies (since they don’t use tox heavy metals such as cadmium or lead), amorphous silicon cells have low efficiency. That plus heavy competition from conventional crystalline silicon cells and other thin-film technologies such as CdTe and CIGS, amorphous silicon has only about 2 percent of the global PV market, as of 2013.

CdTe has a global PV market share of about 5.1 percent. CdTe stands for cadmium telluride photovoltaics. Cadmium telluride is a stable crystalline compound formed from cadmium and tellurium. It’s usually sandwiched with cadmium sulfide to form a p-n junction solar PV cell. CdTe is the only thin film technology with lower costs than conventional solar cells made of crystalline silicon in multi-kilowatt systems. It also has the smallest carbon footprint, lowest water use and shortest energy payback time (less than a year) of all solar technologies. CdTe is used in some of the world’s largest solar PV power stations such as the Topaz Solar Farm in San Luis Obispo County in California.

As for cell efficiency, the average production line module efficiency for CdTe PV was about 17 percent in 2017 but it’s expected that almost 20 percent efficiency is achievable.

The next thin film category is CIGS, which as a 2 percent global PV market share as of 2013. CIGS stands for copper indium gallium selenide solar cell. It’s manufactured by applying layers of copper, indium, gallium and selenium on glass or plastic backing with electrodes on the front and back to collect current. CIGS has a high absorption coefficient and therefore absorbs the sunlight well. Though CIGS outperforms polysilicon at the cell level, the overall module efficiency is still lower due to less mature upscaling. Lab cell tests show about the same level of efficiency as that of CdTe in the 21.5 to 21.7 percent cell efficiency. Average production line module efficiency is lower.

Overall, thin film market share has lost significant market share to conventional solar cells made of crystalline silicon. Though they promise silicon-like efficiencies with lower costs and lower carbon footprint, they are struggling to compete with conventional solar cells.

Next Tuesday, I will discuss multi-junction photovoltaic cells that are neither first or second generations.

Don’t forget to subscribe to Climate Change with Scott Amyx on Amazon Alexa and give it a 5-star rating.